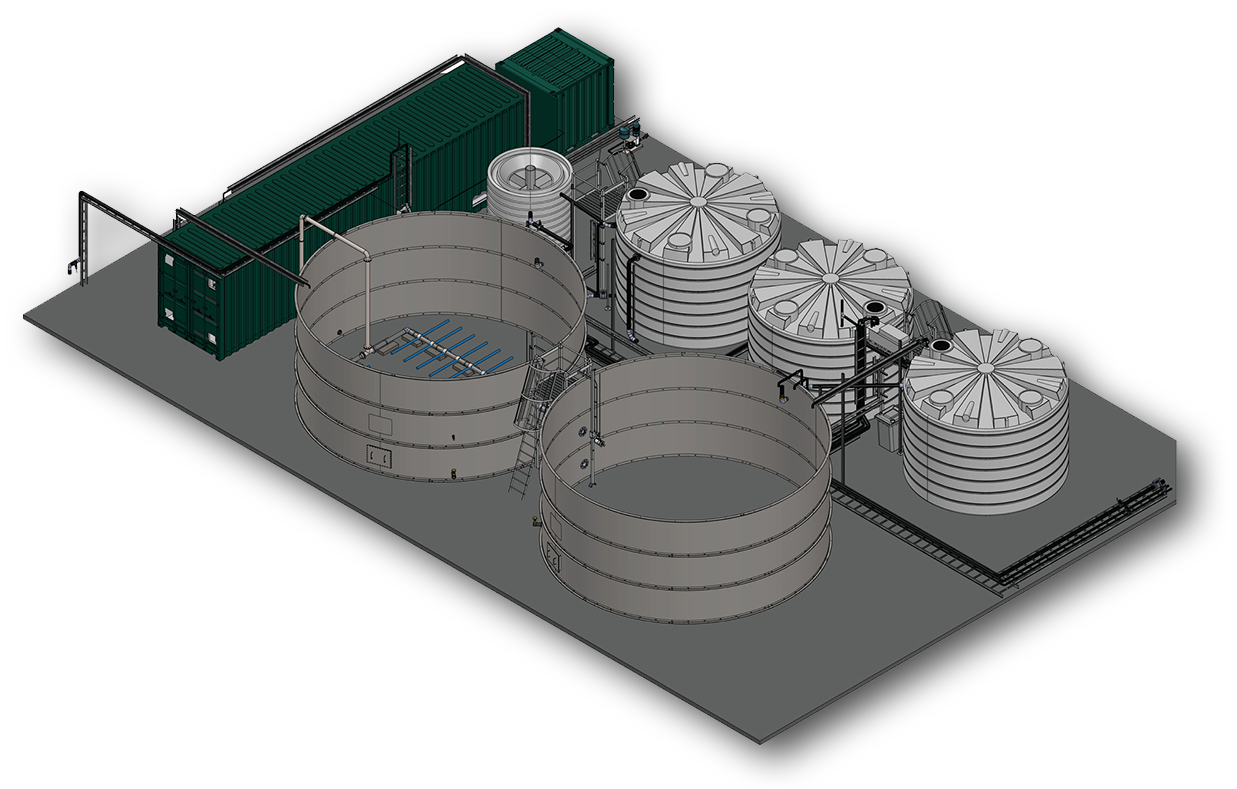

Modified Ludzack-Ettinger (MLE) Process

Advanced Biological Nutrient and BOD Removal

The Modified Ludzack-Ettinger (MLE) process is a robust, proven method for the biological treatment of wastewater, offering simultaneous removal of nitrogen compounds and biochemical oxygen demand (BOD). By integrating anoxic and aerobic zones with internal nitrate recycling and return activated sludge, the MLE process is designed to achieve high-efficiency nutrient removal, stable biological performance, and compliance with strict effluent standards.

KEY BENEFITS

Comprehensive Nitrogen and BOD Removal

- Achieves simultaneous denitrification, nitrification, and organic load reduction (BOD removal) in a single streamlined process.

Optimised Energy Use

- Efficient aeration control in the aerobic zone minimises energy demand without compromising treatment performance.

Reduced Chemical Dependency

- Utilises the natural carbon in the influent as an energy source for denitrification, reducing or eliminating the need for external carbon dosing.

Scalable and Flexible Design

- Suitable for a wide range of applications, from municipal and regional systems to industrial treatment facilities, with capacity for future expansion.

Reliable and Low Maintenance

- A well-established process with straightforward operational control, suited to both experienced operators and low-supervision environments.

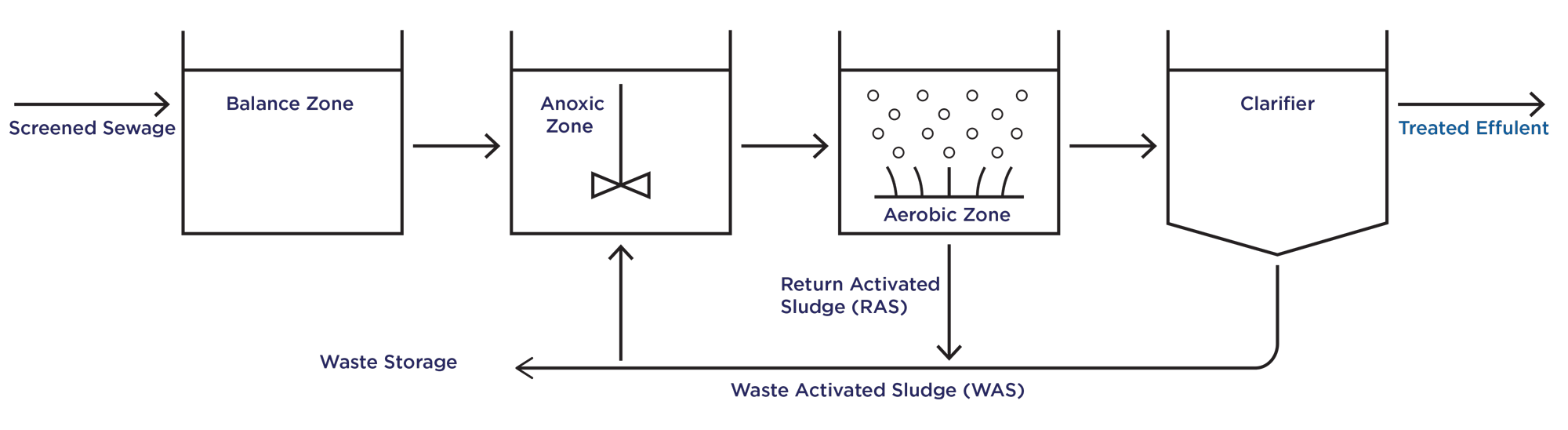

How Does the MLE Process Work?

The MLE process utilises a four-stage biological treatment train, enabling the breakdown of both nitrogen compounds and organic material (BOD).

1. Anoxic Zone (Denitrification)

Raw wastewater enters the anoxic zone, where it is mixed with:

- Return Activated Sludge (RAS) from the clarifier

- Nitrate-rich mixed liquor recycled from the aerobic zone

In the absence of oxygen, facultative bacteria use the organic carbon in the influent to convert nitrates (NO₃⁻) into nitrogen gas, a process known as denitrification.

2. Aerobic Zone (Nitrification & BOD Removal)

The flow continues into the aerobic zone, where:

- Heterotrophic bacteria break down organic matter (removing BOD)

- Nitrifying bacteria convert ammonia (NH₃) to nitrates (NO₃⁻) This zone is supported by mechanical blowers, fine bubble aeration, and dissolved oxygen (DO) controllers to maintain optimal aerobic conditions.

3. Clarifier (Solids Separation)

The mixed liquor passes into a secondary clarifier, where biomass (activated sludge) is settled out.

- A portion of this sludge is returned as RAS to the anoxic zone

- Excess sludge is periodically wasted for disposal

4. Internal Recycle Loop

Nitrate-rich mixed liquor from the aerobic zone is continuously recirculated back to the anoxic zone to sustain denitrification, creating a closed biological loop.

What Makes the MLE Process Unique?

Dual Functionality

- Combines organic and nitrogen removal in a single compact footprint, reducing the need for separate process trains.

Simple Control Philosophy

- Aeration and recirculation are the primary control levers, making the process easy to manage while delivering consistent performance.

Process Versatility

- Suitable for both new builds and retrofit upgrades, especially where nutrient discharge limits must be met.

Proven Track Record

- Widely adopted worldwide for municipal and industrial wastewater treatment, with decades of data supporting its effectiveness.

Experience the MLE Advantage

At Nova Process, we design and supply customised MLE systems that deliver reliable treatment performance, energy-efficient operation, and full biological nutrient removal (BNR). Whether as a standalone plant or integrated into a broader treatment strategy, the MLE process ensures that your wastewater system remains compliant, sustainable, and future-ready.